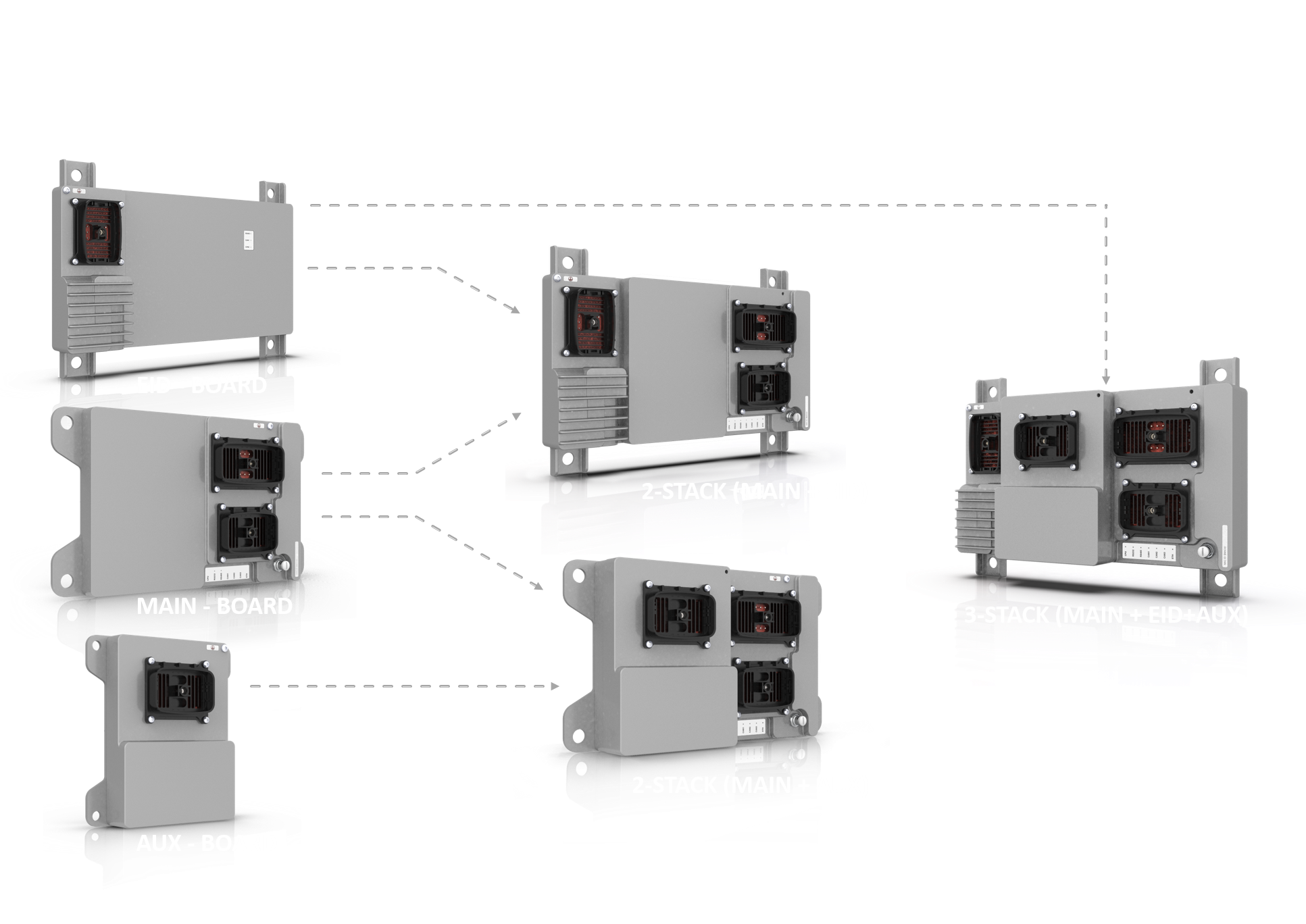

LARGE ENGINE CONTROL MODULE for upgrade Woodward obsolute 700 series. [700, 721, 723, 723+]

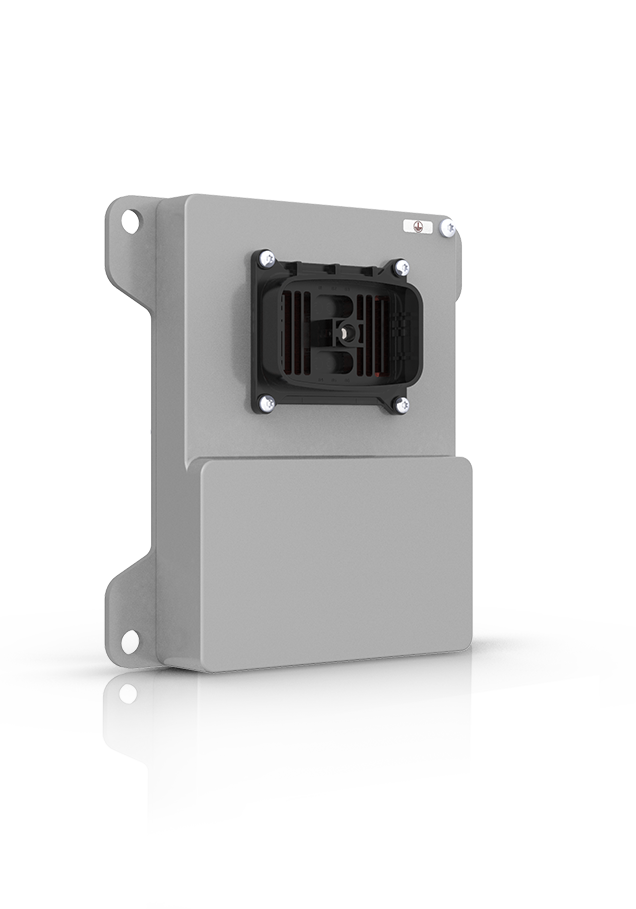

MAIN: ENGINE CONTROL UNIT

The LECM Main module offers an advanced hardware architecture with a powerful processor and extensive I/O and Ethernet to support the evolving needs of Large Engines. Ethernet can be used for a service interface, an HMI/PLC interface using Modbus TCP/IP, for remote diagnostic emails, and for an IIOT interface to a local gateway.

AUX: COMBUSTION CONTROL

24-channel analog inputs can be configured as knock, pressure or thermocouple input. The Aux hardware supports FFT-based knock detection, advanced knock: pressure sensor assist for knock calibration, in-cylinder pressure-based, real-time combustion diagnostics & control (RT-CDC) and thermocouple monitoring.

EID (ELECTRONIC IGNITION/INJECTION DRIVER) MODULE

One 20-channel module to drive any combination of injector (main chamber, pre chamber, micropilot & common rail) and ignition. Programmable current profile offers the ability to meet any desired energy delivery.

Subsea7 Seaway Phoenix engine control upgrade.

Conventional fuel rack actuated Diesel engine applications

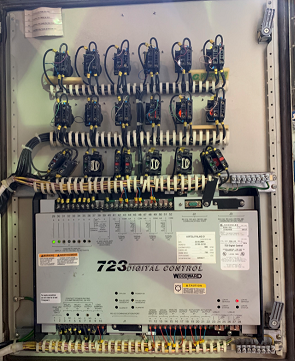

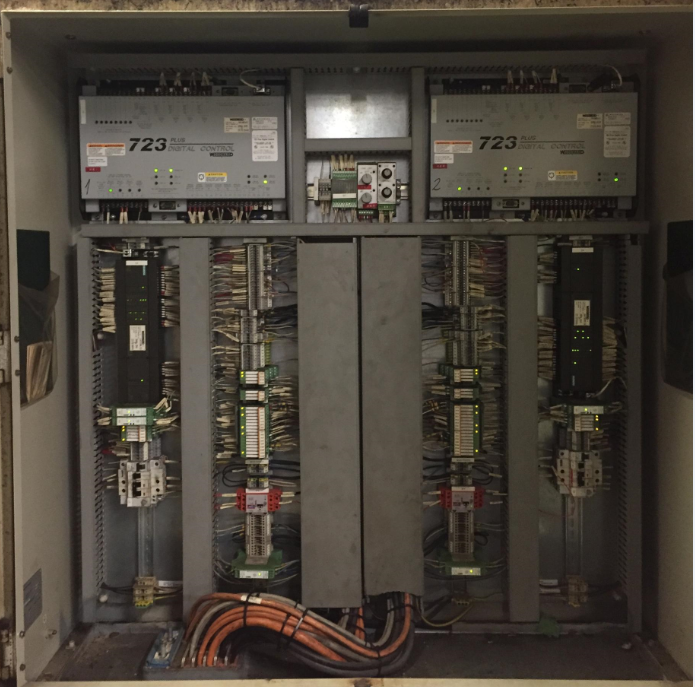

723: MAIN ENGINE CONTROL

The 723 control was installed in 2001 and has been in service for 20 years without interruption.

The 723 has been succeed by the 723+. The last one became obsolute in 2020.

UPGRADE

The Seaway Phoenix has four Wartsila 8R32LNE main engines for Diesel electric propulsion

Removing the 723 and installing the LECM toke one day pro engine

The well proven logic from the 723(+) is re-used. To minimize rewiring, testing and training crew.

The free 'Control Assistant' software is used for commissioning, tuning and monitoring.

LECM

The Woodward LECM is the new large engine control module which replace the 723. The voltage and LON load share lines are replaced with CAN and are redunanded. Communication is now done over ethernet for monitoring and commissioning

DSDF Princess Seaways - Twin Engines

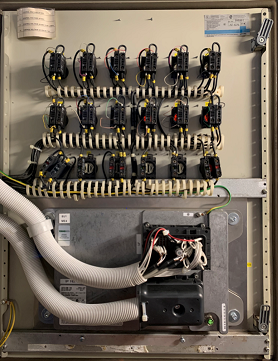

723+: MAIN ENGINE CONTROL

The 723+ controls and a plc were installed in 2003 and has been in service for 18 years without interruption.

The 723+ became obsolute in 2020.

UPGRADE

The Seaway Princess has four MaK 8 M522 main engines for twin propulsion.

The well proven logic from the 723(+) is re-used and the plc functions are added together in the LECM. To minimize rewiring, testing and training of crew.

The free 'Control Assistant' software is used for commissioning, tuning and monitoring.

There is also a toolkit and a HMI screen is added for reading out the LECM and FLEX500

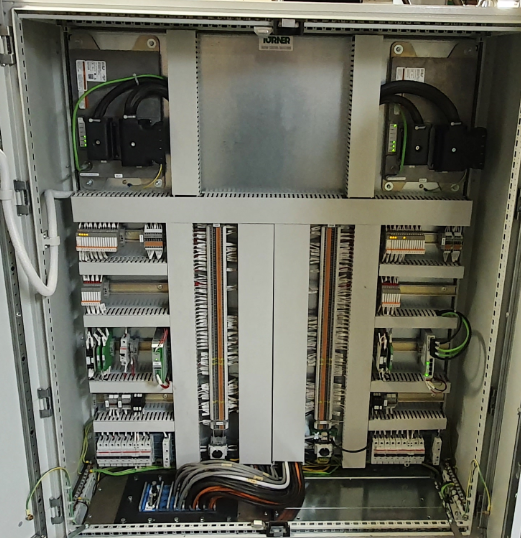

LECM

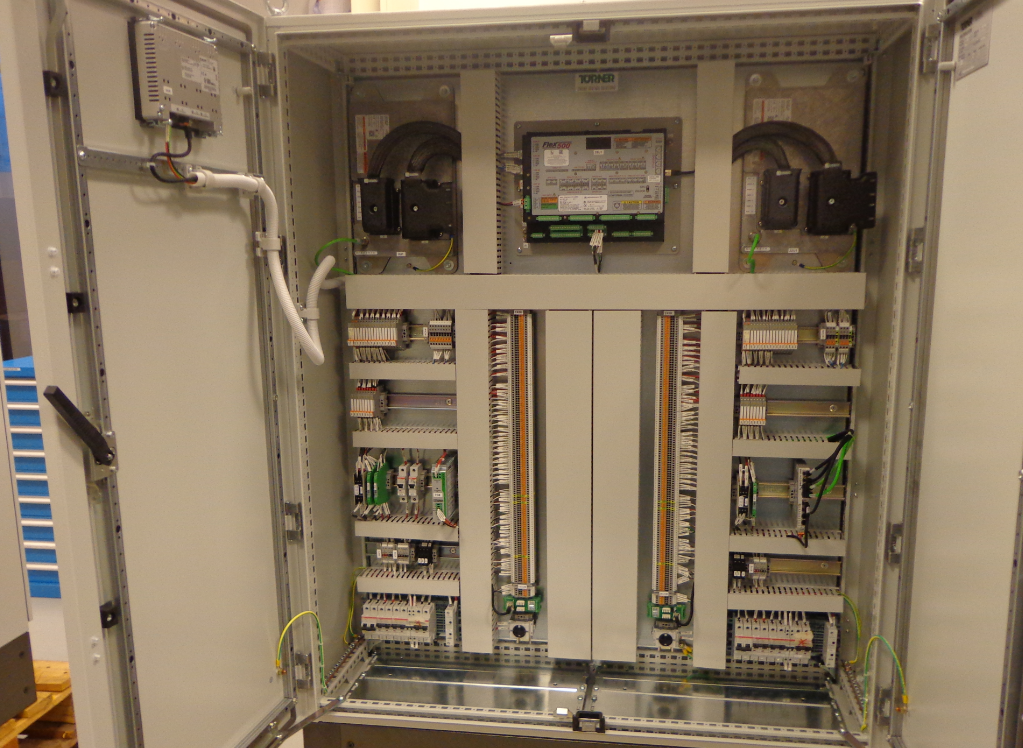

The Woodward LECM is the new large engine control module which replace the 723+ and the plc. The cabinets also got a small HMI screen. There has been also a FLEX500 added for phase matching of the two propellers.

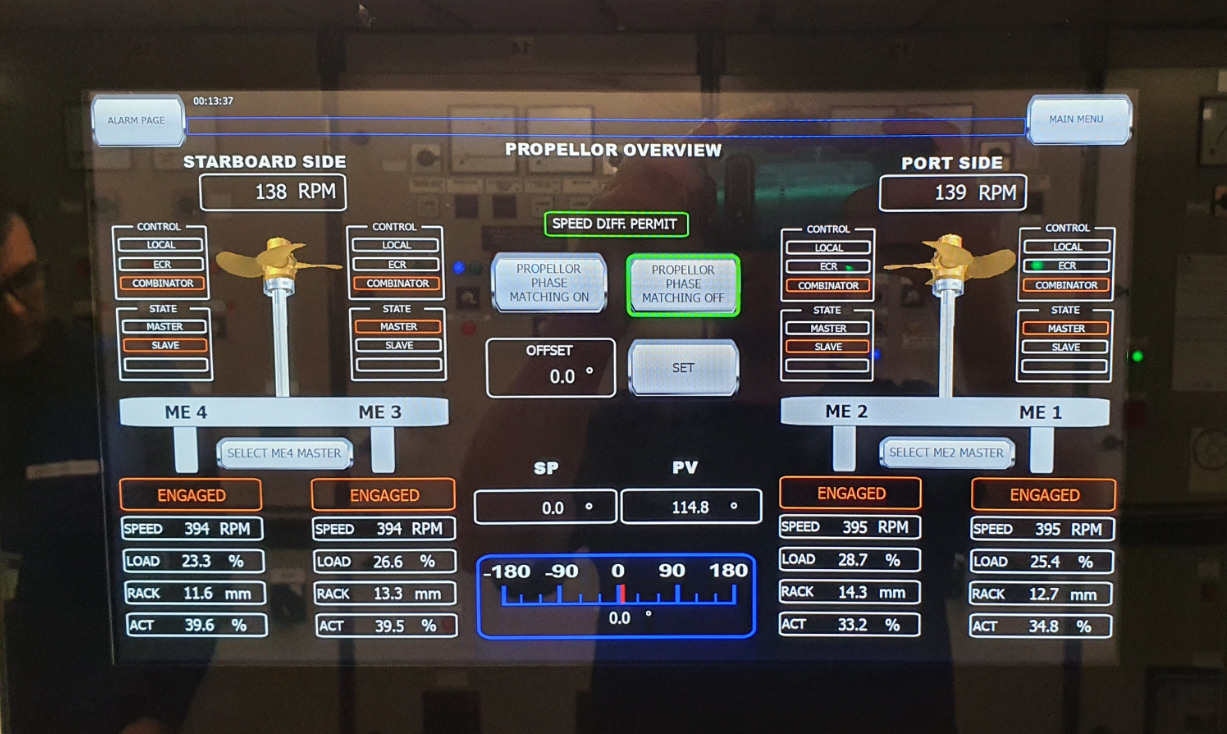

HMI

The LECM has a varaity of communication port which makes it possible to at a HMI

RS-232, RS-485, CAN and ethernet, for Modbus, CANOpen, CAN J1939, Servlink and XCP.

UPGRADE

The old cabinet with 723+ were removed.

New cabinates with the LECM were offshore build and tested.

In GAP4 are the LECM and Flex500 programmed and tested with NETSim.

FLEX500 syncro phaser

The FLEX500 does phase matching of the two propellers.

LECM for upgrade Woodward 723PLUS Digital Speed Control for Reciprocating Engines

8280-410, 8280-411

LECM for upgrade Woodward 723PLUS Digital Speed Control for Single Engine Marine Propulsion Applications

8280-419

LECM for upgrade Woodward 723 & 723PLUS Propulsion Control for Wärtsilä

8280-505, 8280-506

This application will be one to one implement in the LECM or could be expand with extra customer features.

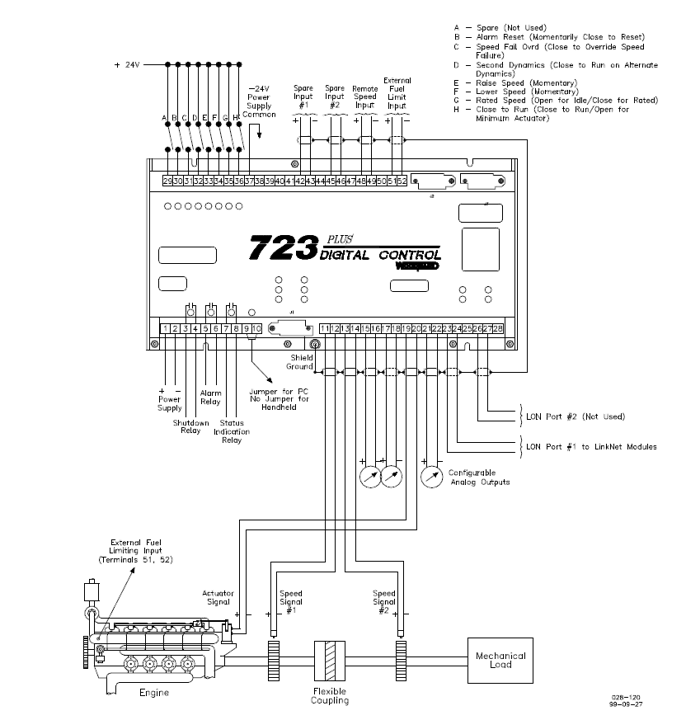

This 723PLUS Digital Industrial Speed Control controls the speed of reciprocating engines in variable speed applications, including those with flexible couplings (see Figure). The control includes inputs for two magnetic pickups (MPUs) or proximity switches for monitoring flexible coupling torsionals, an input for a remote speed setting, an input for output fuel limiting, an internal speed reference for local control of speed, and two spare analog inputs.

MAIN:LECM

Extra features could be;

Turbo speed input

8 thermocouples

Oil pressure

Oil temperature

Eternet-modbus to upper system

Sequency logic

MAIN+AUX:LECM

With 2-stack

24 extra thermocouples/RTD

2-10 fast pressure cilinder measurments

LECM for upgrade Woodward 721 Digital Control for Droop/Isochronous Tandem Propulsion Control

8280-321

LECM for upgrade Woodward 723 & 723PLUS Digital Speed Control for Two-engine Mechanical Load Sharing

8280-208, 8280-422, 8280-423

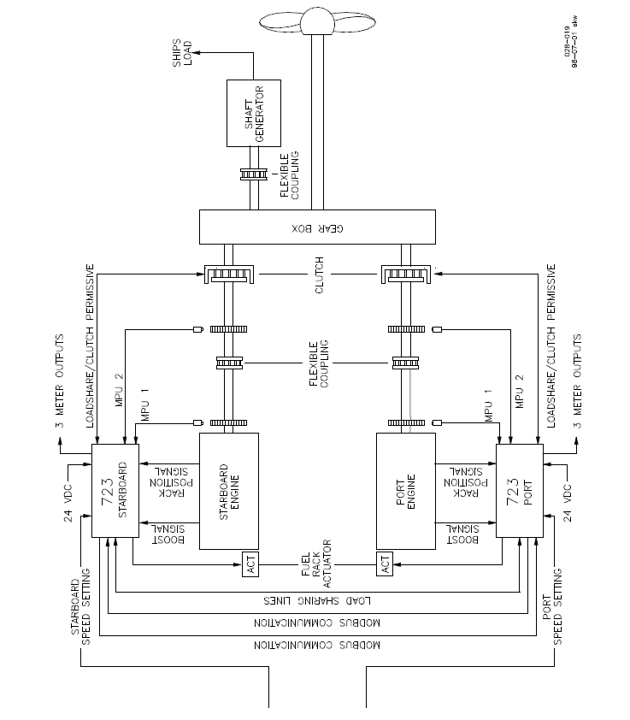

This application will be one to one implement in the LECM or could be expand with extra customer features.

These controls are designed to regulate the speed and load of diesel engines in dual-engine marine applications that require mechanical load sharing. The applications include mechanically combined two-engine operation for main propulsion and dredge operation, including those with flexible couplings.

MAIN:LECM

Extra features could be;

Turbo speed input

8 thermocouples

Oil pressure

Oil temperature

Eternet-modbus to upper system

Sequency logic

MAIN+AUX:LECM

With 2-stack

24 extra thermocouples/RTD

2-10 fast pressure cilinder measurments

LECM for upgrade Woodward 723 & 723PLUS Digital Speed Control for Analog Load Sharing

9907-035, 9907-036, 9907-037, 9907-038, 8280-419

LECM for upgrade Woodward 723 & 723PLUS Generator Control for Wärtsilä

8280-500, 8280-501, 8280-502, 8280-503, 8280-5000, 8280-5010, 8280-5020 and 8280-5030

This application will be one to one implement in the LECM or could be expand with extra customer features.

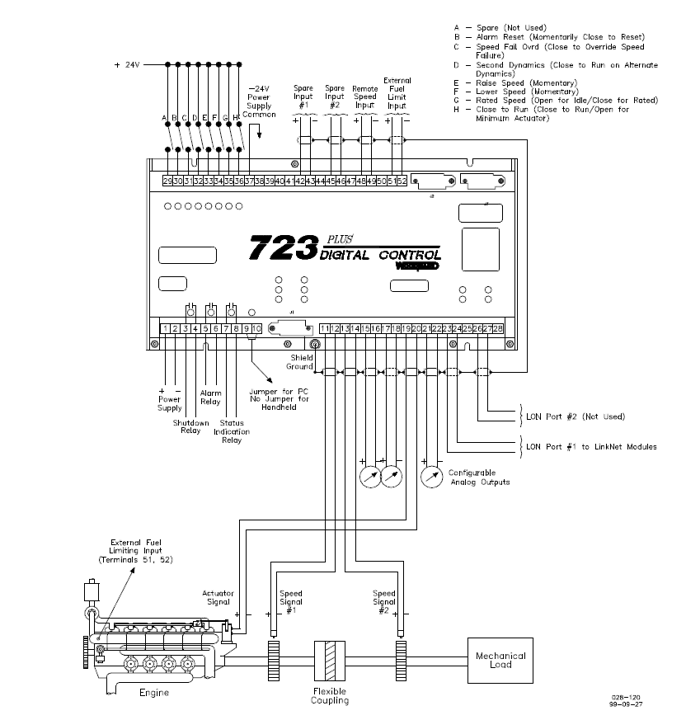

This 723PLUS Digital Industrial Speed Control controls the speed of reciprocating engines in variable speed applications, including those with flexible couplings (see Figure). The control includes inputs for two magnetic pickups (MPUs) or proximity switches for monitoring flexible coupling torsionals, an input for a remote speed setting, an input for output fuel limiting, an internal speed reference for local control of speed, and two spare analog inputs.

MAIN:LECM

Extra features could be;

Turbo speed input

8 thermocouples

Oil pressure

Oil temperature

Eternet-modbus to upper system

Sequency logic

MAIN+AUX:LECM

With 2-stack

24 extra thermocouples/RTD

2-10 fast pressure cilinder measurments